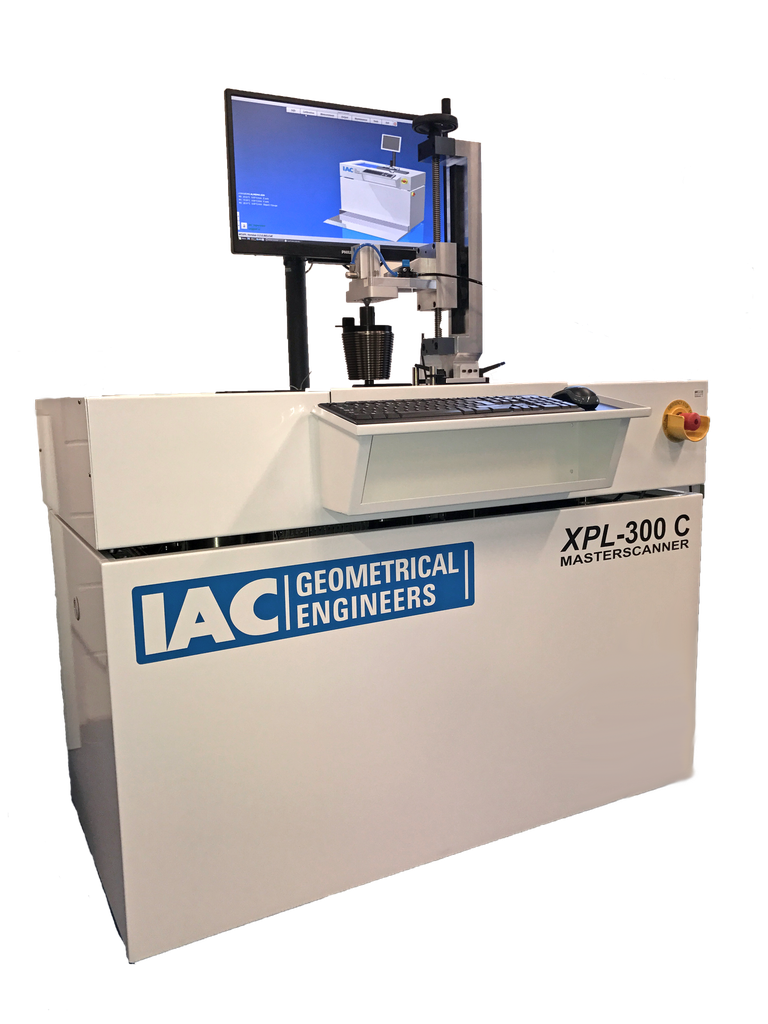

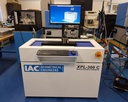

XPL-C Series

- 外径測定範囲:1.0~190/290mm(モデルにより異なります)

- 内径測定範囲:2.5~200/300mm(モデルにより異なります)

- 最大測定長:100mmまたは200mm(モデルにより異なります)

- 最小ねじピッチ:0.1mm

- 重量:620kg

- 花崗岩製ベッド

- 水平/垂直ガイド:精密エアベアリング

- 駆動方式:スイス製ブラシレスモーター

- 測定システム:ハイデンハイン製インクリメンタルリニアエンコーダシステム

- 分解能:0.01μm

- ケーブル付きインターフェースボックス

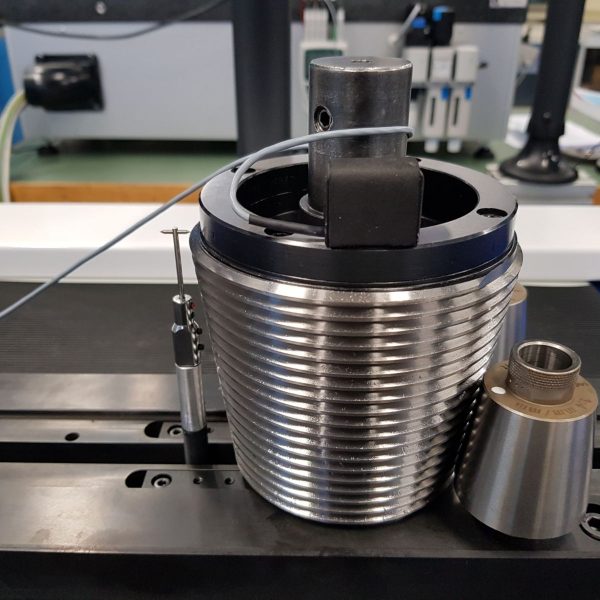

- Click'Onクイックチェンジシステム

- 産業用制御コンピュータ

- キーボード、マウス、フラットスクリーン

- 購入規格の校正証明書

- 機械軸のレーザー校正証明書

- MSProg LINUXソフトウェアパッケージ(多言語対応)

- IACLIB(標準公差ライブラリ)

- 検査合格後1年間の保証お客様

- MSProgおよび購入モジュールの1年間無料アップデート

Masterscanner XPL-C Series Full-automated measurement, without human intervention, the machine displays all measured thread parameters per pitch in under 2 minutes. All measured values are compared with the built-in thread standards library, the system generates the measuring report automatically. The MasterScanner significantly reduces human error, as well as improves the measuring efficiency, quality, consistency and accuracy of the results. The MasterScanner is compliant with all requirements

for tractability of today as stated in ISO-9000 and ISO/IEC 17025:2017.

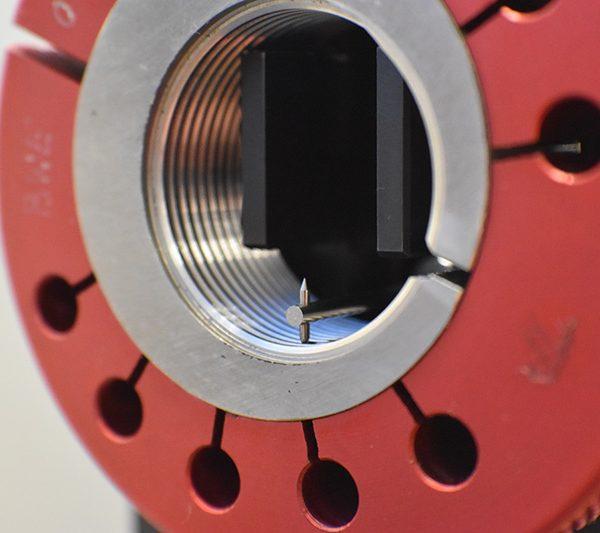

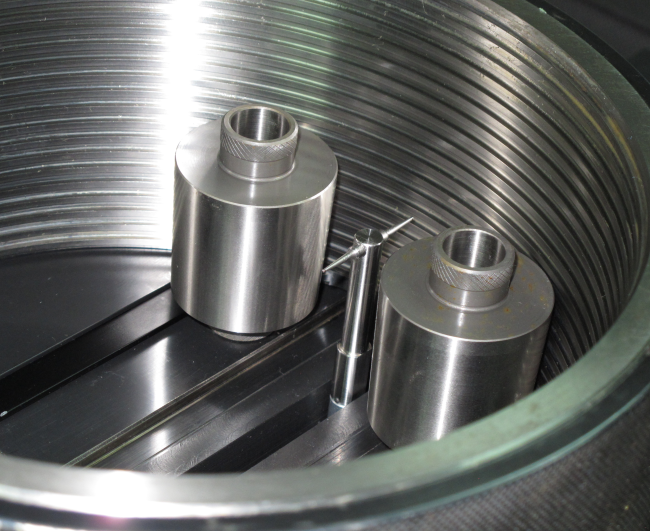

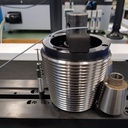

Get all parameters of cylindrical thread plug gauges, cylindrical thread ring gauges, taper thread plug gauges, taper thread ring gauges, plain ring gauges, plain plug gauges and other gauges with internal & external dimensions, including virtual pitch diameter , single pitch diameter, basic pitch diameter, major diameter, minor diameter, thread pitch, thread angle, half of thread angle, flank straightness, lead angle, taper, perpendicularity, etc.

| MEASURING UNCERTAINTY: | ||

|---|---|---|

| XPL-C MODELS | XPL-C-200 | XPL-C-300 |

| Thread ring gauges, parallel or tapered (minor diameter > 10mm, partial flank angles ≥ 27º) | ||

| Minor diameter | 3,0 μm + 5.10-6·ι | 3,0 μm + 5.10-6·ι |

| Effective pitch diameter | 3,0 μm + 5.10-6·ι | 3,0 μm + 5.10-6·ι |

| Thread pitch | 1,0 μm + 5.10-6·ι | 1,0 μm + 5.10-6·ι |

| Flankangles (right and left side) | 0°6’0” | 0°6’0” |

| Taper | 0,1° | 0,1° |

| Thread ring gauges, parallel or tapered (minor diameter 2,5 to 10 mm, partial flank angles ≥ 27º) | ||

| Minor diameter | 3,5 μm + 5.10-6·ι | 3,5 μm + 5.10-6·ι |

| Effective pitch diameter | 3,5 μm + 5.10-6·ι | 3,5 μm + 5.10-6·ι |

| Thread pitch | 1,0 μm + 5.10-6·ι | 1,0 μm + 5.10-6·ι |

| Flankangles (right and left side) | 0°6’0” | 0°6’0” |

| Taper | 0,1° | 0,1° |

| Thread plug gauges, parallel or tapered (major diameter > 1 mm, partial flank angles ≥ 27º) | ||

| Minor diameter | 3,0 μm + 5.10-6·ι | 3,0 μm + 5.10-6·ι |

| Effective pitch diameter | 3,0 μm + 5.10-6·ι | 3,0 μm + 5.10-6·ι |

| Thread pitch | 1,0 μm + 5.10-6·ι | 1,0 μm + 5.10-6·ι |

| Flankangles (right and left side) | 0°6’0” | 0°6’0” |

| Taper | 0,1° | 0,1° |

| Plain gauges, parallel or tapered (Diameter > 10 mm) | ||

| Plain ring gauge | 2,0 μm + 5.10-6·ι | 2,0 μm + 5.10-6·ι |

| Plain plug gauge | 2,0 μm + 5.10-6·ι | 2,0 μm + 5.10-6·ι |

| Taper | 0,1° | 0,1° |

| Plain cylindrical or Taper gauge (Diameter from 1mm to 10mm) | ||

| Plain ring gauge | 3,0 μm + 5.10-6·ι | 3,0 μm + 5.10-6·ι |

| Plain plug gauge | 3,0 μm + 5.10-6·ι | 3,0 μm + 5.10-6·ι |

| Taper | 0,1° | 0,1° |